Back to Product Page

|

UNICLAMPS™

Lightweights - Middleweights - Heavyweights

|

|

|

|

| Uniclamp™

Welding Hold Down Clamp |

|

See

below for all models to suit your needs. |

|

|

|

|

|

|

WHAT

IT DOES:

|

|

|

|

|

|

|

|

|

UNICLAMP™

ELIMINATES THE GAP BETWEEN THE PLATE AND THE STIFFENER!

|

|

|

|

|

|

|

|

This

conventional setup can take up to two hours to

complete, The process including welding lugs, dogs

and bridges in place - positioning awkward and heavy

equipment - then removing these setups and cleaning

up the attachment points. |

|

The

UNICLAMP™ takes less than 30 seconds to

set up - increasing productivity, safety and quality. |

|

|

|

|

|

|

HOW

IT WORKS:

|

|

The

simple connection of a standard plant-supplied compressed air

line and the flick of a switch allows the clamp’s

built-in, high speed generator to create a powerful vacuum,

permitting the vacuum pads to immediately attach them-

selves directly to the work surface. The clamp manual screw

or hydraulic ram can then be operated to instantly secure

the proper alignment of parts. UNICLAMPS™ will meet your

clamping requirements without the tedious, time

consuming and sometimes dangerous paraphernalia associated with

traditional methods of fabrication assembly

techniques. NO MORE LUGS DOGS, BRIDGES, WEDGES, CHAINS, JACKS,

C-CLAMPS, TACK WELDS,

OR REGRINDING REQUIRED! |

|

|

UNICLAMPS™

Are Powered by Compressed Air and Leave No Marks!

NOTE: UNICLAMPS™ ARE NOT DESIGNED FOR LIFTING PURPOSES.

|

|

UNIVAC®

Vacuum Lifters are designed for efficient, one-person operation

in lifts of semi-porous and non-porous

material. Unlike magnets or edge grabs, vacuum units will not

mark or scratch material surfaces or edges. Additionally,

vacuum lifters can easily lift nonferrous metals and thin sheets

(under 1/4"). |

|

|

|

| Benefits

your company will receive with UNIVAC® Vacuum Lifters: |

•

Increase productivity, reducing cost.

• One person operation.

• Eliminate material damage.

• Precision handling made easier. |

|

•

Versatile handling of most materials.

• Improve storage space.

• Provide a low maintenance lifter.

• Durable for long lasting service. |

|

|

|

| ALL

UNIVAC® Lifters Have: |

•

Registered nameplates as required by ASME.

• Rated capacities and product safety labels. |

|

|

|

UNIVAC®

Vacuum Lifters adhere to the highest quality standards in

the industry and all units conform to ASME

standards. All UNIVAC® Vacuum Lifters are designed with

a 2 to 1 vacuum safety factor. |

|

|

|

| Delivery

Program |

Look

for the red QUICKSHIP logo

on our standard products. The specific QUICKSHIP model number

is shown

in red. QUICKSHIP

products ship in 7 to 10 days (excluding weekends and holidays). |

|

|

|

| Industry

Standard |

The

American Society of Mechanical Engineers (ASME) has developed

standards that apply specifically to these

types of devices. ASME B30.20 provides detailed information

on the classifications, marking, construction, installation,

inspection, testing maintenance and operation of below the hook

lifting devices. ASME BTH-1 provides detailed

information on the design criteria of below the hook lifting

devices. These standards serve as a guide to government

authorities, manufactures, purchasers and users of lifting devices.

For

a summary of these standards, please click

on this link. |

|

|

|

|

|

|

|

|

|

|

THE

LIGHTWEIGHTS...

|

|

|

|

|

WHD-1

and WHD-2 models are constructed of a high-strength aluminum

bringing lightweight portability to

workpiece positioning and clamping. |

|

|

|

|

The

UNICLAMPS™ have proved to be invaluable in transportation

industry applications. These easy to position

clamps are ideally suited for sheet and light plate fabrication.

Lightweight UNICLAMPS™ are used to secure “skin”

materials to ribbed structures at aircraft, aerospace, bus,

trailer, and truck manufacturing facilities. |

|

|

|

|

|

|

|

|

|

|

The

WHD-1 and WHD-2 UNICLAMPS™ feature capacities

up to 1,200 lbs with clamp weights not exceeding 16 lbs!

Features include round or rectangular vacuum pads, varying

headframe widths, and varying height under the ram to suit

special requirements. |

|

|

|

|

|

|

|

|

SPECIFICATIONS

|

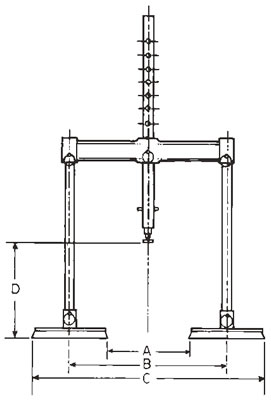

Model

No. |

Holding

Force

(lbs.) |

D

Height Under

Ram (in.) |

Dimensions (in.) |

Weight

(lbs.) |

Round

Vacuum Pads |

Rectangular

Vacuum Pads |

|

A |

B |

C |

A |

B |

C |

|

WHD-1 |

750 |

8-3/4 |

8-1/4 |

15-1/2 |

22-3/4 |

12 |

15-1/2 |

19 |

14 |

|

WHD-2 |

1200 |

8-3/4 |

5-7/8 |

15-1/2 |

25-1/8 |

12 |

15-1/2 |

19 |

16 |

|

NOTE:

Weights and dimensions are approximate.

*Call sales department for a quote to your specifications. |

|

|

UNICLAMPS™

Disassemble in Seconds Without Tools!

NOTE: UNICLAMPS™ ARE NOT DESIGNED FOR LIFTING PURPOSES.

|

|

|

|

|

|

THE

MIDDLEWEIGHTS...

|

|

|

|

|

|

|

|

Like

their smaller counterparts, the UNICLAMP™

models WHD-18, WHD-24, WHD-32 and WHD-40

are constructed of high-strength aluminum affording these

clamps the identical advantage of reduced weight for

heavier duty positioning and clamping requirements. |

|

|

|

|

|

|

|

The

clamp models are used extensively in aircraft, ship

building, bridge construction, tank manufacturing and the

steel fabrication industry. They excel whenever larger

assemblies need to be drawn into alignment or held in

position for a welding process. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The

WHD-18 and WHD-24 UNICLAMP™

features include round or rectangular vacuum pads,

varying headframe widths, and varying height under

the ram to suit special requirements. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The

WHD-32 and WHD-40 are available with

round, rectangular or square vacuum pads,

varying headframe widths, and varying height

under the ram to suit special requirements.

|

|

|

|

|

|

|

|

|

|

|

|

|

SPECIFICATIONS

|

|

Model

No.

|

Holding

Force

(lbs.)

|

D

Height Under

Ram (in.)

|

Dimensions (in.)

|

Weight

(lbs.)

|

|

Round Vacuum Pads

|

Rectangular Vacuum Pads

|

|

A

|

B

|

C

|

A

|

B

|

C

|

|

WHD-18 |

1800 |

15-3/4 |

13-3/4 |

24 |

34-1/4 |

20 |

24 |

28 |

34 |

|

WHD-24 |

2400 |

15-3/4 |

12 |

24 |

36 |

19 |

24 |

29 |

36 |

|

WHD-32 |

3200 |

15-3/4 |

10 |

24 |

38 |

15 |

24 |

33 |

38 |

|

WHD-40 |

4000 |

15-3/4 |

8 |

24 |

40 |

15 |

24 |

33 |

42 |

|

NOTE:

Weights and dimensions are approximate.

*Call sales department for a quote to your specifications. |

|

|

Concave

or Convex Surfaces, No Problem for UNICLAMPS™!

NOTE: UNICLAMPS™ ARE NOT DESIGNED FOR LIFTING PURPOSES.

|

|

|

THE

HEAVYWEIGHTS...

|

|

|

|

|

|

UNICLAMP™

steel constructed models WHD-60, WHD-80 and WHD-100 answer industry’s

heaviest application

requirements. |

|

|

|

|

|

Used

in ship building, heavy plate fabrication, plant construction,

bridge building, large tank fabrication, these clamps

bring incredible amounts of clamping power to bear on the largest

of fabrication application requirements. These

easy-to-use, portable, high-speed clamps draw oversize materials

into position for welding, assembly or alignment

procedures. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The

WHD-60, WHD-80, and WHD-100 Welding and Fabrication Clamps,

boast holding force up to 10,000 lbs

with a venturi vacuum generator and a hydraulic powered ram

as standard features. Vacuum pads in round,

rectangular, or square are available to suit custom requirements. |

|

|

|

|

|

|

SPECIFICATIONS

|

Model

No. |

Holding

Force

(lbs.) |

D

Height Under

Ram (in.) |

Dimensions (in.) |

Weight

(lbs.) |

|

Round Vacuum Pads |

Rectangular Vacuum Pads |

|

A |

B |

C |

A |

B |

C |

|

WHD-60 |

6000 |

24 |

19 |

31 |

50 |

17 |

26 |

35 |

165 |

|

WHD-80 |

8000 |

24 |

14 |

37 |

60 |

15 |

29 |

43 |

195 |

|

WHD-100 |

10000 |

30 |

12-1/2 |

40 |

67-1/2 |

17 |

38 |

59 |

245 |

|

NOTE:

Weights and dimensions are approximate.

*Call sales department for a quote to your specifications. |

|

|

UNICLAMP™

APPLICATIONS

|

|

Whether

work surfaces are angled, inclined, right angles, convex or

concave, UNICLAMPS™ provide the best

solution for your positioning and clamping needs. |

|

|

|

Uniclamps, Lightweight

Uniclamp, Middleweight Uniclamp, Heavyweight Uniclamps, Welding

Hold Down Clamp,

Welding Clamp, Securing Clamp, Aligning Clamp, Portable Clamp,

High Speed Clamps, and Assembly Clamps from

your source for material handling equipment.

|

Back to Product Page

|