Back to Product Page

|

TUFLEX

POLYESTER SINGLE LEG

ROUNDSLINGS WITH HARDWARE

|

|

|

|

|

|

|

|

|

| Features,

Advantages and Benefits |

Maintains

all the basic Tuflex features plus ... |

|

|

|

|

|

|

|

|

|

Promotes

Safety |

|

|

|

|

|

|

|

|

|

|

|

•

Bridles provide better load control and balance. |

|

|

|

|

|

|

|

|

|

|

•

Use of hardware prevents cutting and abrasion

of sling at bearing points. |

|

|

|

|

|

|

|

|

|

|

Saves

Money |

|

|

|

|

|

|

|

|

|

|

•

Reduces damage by protecting load between

pick-up point and crane hook. |

|

|

|

|

|

|

|

|

|

|

Saves

Time |

|

|

|

|

|

|

|

|

|

|

•

Lightweight and pliable for easy rigging and storage.

|

|

|

|

|

|

|

|

|

|

•

Sling hooks quickly connect to loads having

hoist rings or eye bolts. |

|

|

|

|

|

|

|

|

|

|

How

to Order |

|

|

|

|

|

|

|

|

|

Specify:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.

Number of legs- |

|

|

|

|

|

|

Example: |

|

|

S

(Single-1) |

|

|

|

|

|

|

|

|

|

|

SOS-EN-90

x 10' is a single leg bridle, oblong master

link, with sling hook attached to each Tuflex EN 90.

Assembly length is 10 ft. |

|

|

|

|

|

|

2.

Master Link-O (Oblong) |

|

|

|

|

|

|

|

3.

Bottom Attachments-S (Sling Hook), O (Oblong) |

|

|

|

|

|

|

|

4.

Tuflex Code |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.

Length of Assembly- Feet (Bearing point to bearing point) |

|

|

|

|

|

|

|

|

|

|

Tuflex Size & Color |

Rated

Capacity (lbs.)* |

Hardware |

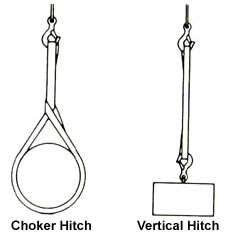

Vertical

|

Choker

|

Basket

@90°

|

Hook

A - Alloy

C - Carbon |

Masterlink

Stock Dia.

(in.) |

|

EN30 |

Purple |

|

2,600

|

2,100

|

5,200

|

2TA

|

1/2

|

|

EN60 |

Green |

|

5,300

|

4,200 |

10,600 |

4.5TA

|

3/4

|

|

EN90 |

Yellow |

|

8,400

|

6,700 |

16,800 |

7TA

|

3/4

|

|

EN120 |

Tan |

|

10,600

|

8,500

|

21,200

|

11TA

|

1 |

|

EN150 |

Red |

|

13,200

|

10,600

|

26,400

|

11TA

|

1 |

|

EN180 |

White |

|

16,800

|

13,400

|

33,600 |

15TA

|

1

1/4 |

|

EN240 |

Blue |

|

21,200

|

17,000

|

42,400

|

22TA

|

1

1/4 |

|

EN360 |

Grey |

|

31,000

|

24,800

|

62,000 |

20TC

|

1

1/2 |

|

EN600 |

Brown |

|

53,000

|

42,400

|

106,000 |

30TC

|

2 |

|

EN800 |

Olive |

|

66,000

|

52,800

|

132,000 |

40TC

|

2

1/4 |

|

EN1000 |

Black |

|

90,000

|

72,000 |

180,000 |

- |

2

1/2 |

|

|

|

* * |

Always

protect roundslings from corners, edges, or protrusions. Refer

to the Sling Protection section below

to choose the right protection product for your lift. |

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Price of the item you

wish to purchase.

|

|

|

|

|

*Contact

Us For Special Lengths*

|

|

|

|

|

|

|

|

|

|

|

PRICING

|

|

|

SINGLE LEG SOS |

|

Tufflex Size |

EN30 |

EN60 |

EN90 |

|

2'

|

|

|

|

|

3'

|

|

|

|

|

4'

|

|

|

|

|

5'

|

|

|

|

|

6'

|

|

|

|

|

7'

|

|

|

|

|

8'

|

|

|

|

|

9'

|

|

|

|

|

10'

|

|

|

|

|

11'

|

|

|

|

|

12'

|

|

|

|

|

13'

|

|

|

|

|

1'

|

|

|

|

|

15'

|

|

|

|

|

16'

|

|

|

|

|

17'

|

|

|

|

|

18'

|

|

|

|

|

19'

|

|

|

|

|

20'

|

|

|

|

|

21'

|

|

|

|

|

22'

|

|

|

|

|

23'

|

|

|

|

|

24'

|

|

|

|

|

25'

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Price of the item you

wish to purchase.

|

|

|

|

|

*Contact

Us For Special Lengths*

|

|

|

|

|

|

|

|

|

|

|

|

SINGLE LEG SO |

|

Tufflex Size |

EN30 |

EN60 |

EN90 |

|

2'

|

|

|

|

|

3'

|

|

|

|

|

4'

|

|

|

|

|

5'

|

|

|

|

|

6'

|

|

|

|

|

7'

|

|

|

|

|

8'

|

|

|

|

|

9'

|

|

|

|

|

10'

|

|

|

|

|

11'

|

|

|

|

|

12'

|

|

|

|

|

13'

|

|

|

|

|

14'

|

|

|

|

|

15'

|

|

|

|

|

16'

|

|

|

|

|

17'

|

|

|

|

|

18'

|

|

|

|

|

19'

|

|

|

|

|

20'

|

|

|

|

|

21'

|

|

|

|

|

22'

|

|

|

|

|

23'

|

|

|

|

|

24'

|

|

|

|

|

25'

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Price of the item you

wish to purchase.

|

|

|

|

|

*Contact

Us For Special Lengths*

|

|

|

|

|

|

|

|

|

|

|

SINGLE LEG SOO |

|

Tufflex Size |

EN30 |

EN60 |

EN90 |

|

2' |

|

|

|

|

3' |

|

|

|

|

4' |

|

|

|

|

5' |

|

|

|

|

6' |

|

|

|

|

7' |

|

|

|

|

8' |

|

|

|

|

9' |

|

|

|

|

10' |

|

|

|

|

11' |

|

|

|

|

12' |

|

|

|

|

13' |

|

|

|

|

14' |

|

|

|

|

15' |

|

|

|

|

16' |

|

|

|

|

17' |

|

|

|

|

18' |

|

|

|

|

19' |

|

|

|

|

20' |

|

|

|

|

21' |

|

|

|

|

22' |

|

|

|

|

23' |

|

|

|

|

24' |

|

|

|

|

25' |

|

|

|

|

|

|

Sling

Protection

|

|

|

CUT

AND WEAR PROTECTION

|

|

|

|

|

|

| Selection

of Sling Protection Products |

|

|

|

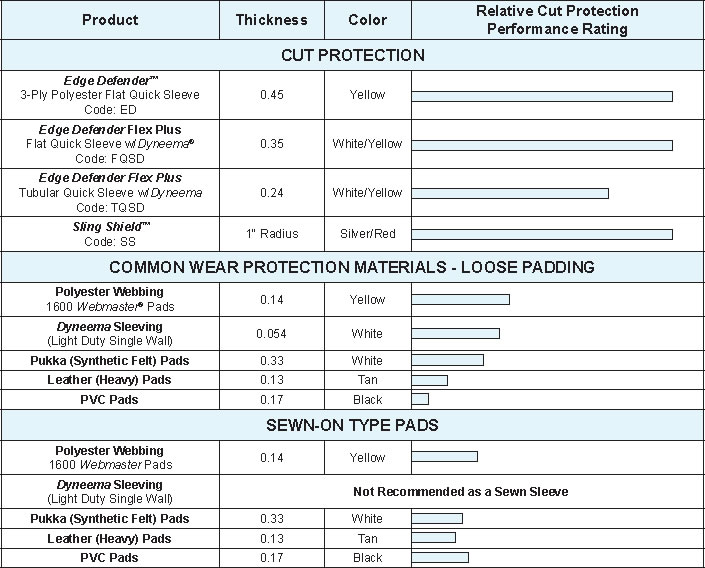

Sling

protection products need to be used in applications where sling

damage may occur. Cutting of synthetic slings during use is

the number

one cause of sling accidents. A variety of factors influence

sling

protection performance. Since no material is fully cut proof,

a qualified

person must select materials and methods that adequately protect

slings from edges or surfaces. We can assist customers with

their

product selections. |

|

|

|

|

|

|

|

| Cut

Protection versus Wear Protection |

|

|

Our

sling protection products are divided into two categories, Cut

Protection and Wear Protection. Cut Protection

Products are designed to improve workplace safety. When placed

between slings and edges, cut protection products

act as a buffer to prevent sling cutting and to reduce bearing

pressure levels at contact areas. Wear protection

products serve to extend sling life by reducing abrasive wear

and prevent marring of the load surfaces.

The following table provides comparative sling protection performance

for standard products. |

|

|

|

Performance

Rating: The bar graphs shown above reflect the comparative

performance of Our Cut Protection

products against commonly used loose and sewn-on types of Wear

Protection products.

Test Lift Qualification: To validate the suitability

of sling protection products for each application, always

complete one or more test lifts in a non-consequence manner.

Technical Bulletin MS-10 available for additional information. |

|

|

|

|

|

|

|

|

|

|

| EFFECT

OF SLING ANGLE |

|

|

|

|

|

|

|

|

|

Using

slings at an angle can become deadly if that angle is

not taken into consideration when selecting the sling to

be used. The tension on each leg of the sling is increased as

the angle of lift, from horizontal, decreases. It is most

desirable for a sling to have a larger angle of lift, approaching

90°. Lifts with angles of less than 30° from horizontal

are not recommended. If you can measure the angle of lift or

the length and height of the sling as rigged, you can

determine the properly rated sling for your lift. The Increased

Tension method provides the increased tension as a

function of the sling angle. Alternatively, the sling Reduced

Capacity method may be used to determine reduced lift

capacity for any angle. |

|

|

|

|

|

|

|

|

|

|

INCREASED

TENSION

Determine capacity

of sling needed

|

|

REDUCED

CAPACITY

Calculate rating of each

sling

rigged at this angle

|

|

|

|

|

|

| 1.

Determine the load weight (LW). |

1.

Calculate the reduction factor (RF). |

|

|

|

|

a.

Using the angle from horizontal,

read across the Angle Chart to

the corresponding number of the

Reduction Factor column. |

| 2.

Calculate the Tension Factor [TF]. |

|

|

a.

Determine the sling angle as mea-

sured from the horizontal, and the

corresponding tension factor (TF)

from the effect of angle chart. |

|

|

|

-OR-

|

|

|

b.

Divide sling height* (H) by sling

length* (L). |

|

-OR-

|

|

|

|

b.

Length* (L) divided by height*

(H) |

|

|

|

|

|

2.

Reduction factor (RF) x the sling’s

rated capacity for the type hitch that

will be used = sling’s reduced rating. |

|

|

|

|

|

|

|

|

|

|

|

|

3.

Determine the share of the load

applied to each sling leg (LW). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.

Multiply (LW) by (TF) to determine

the sling leg tension. The capacity of

the selected sling or sling leg must

meet the calculated tension value. |

|

|

*Measured

from a common horizontal

plane to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

*Measured

from a common horizontal plane

to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Effect

of Angle Chart

|

|

|

|

|

Tension

Factor (TF) |

Angle From

Horizontal |

Reduction

Factor (RF) |

|

1.000 |

90º |

1.000 |

|

1.004 |

85º |

0.996 |

|

1.015 |

80º |

0.985 |

|

1.035 |

75º |

0.966 |

|

1.064 |

70º |

0.940 |

|

1.104 |

65º |

0.906 |

|

1.155 |

60º |

0.866 |

|

1.221 |

55º |

0.819 |

|

1.305 |

50º |

0.766 |

|

1.414 |

45º |

0.707 |

|

1.555 |

40º |

0.643 |

|

1.742 |

35º |

0.574 |

|

2.000 |

30º |

0.500 |

|

|

|

|

|

|

|

|

|

Example: |

|

|

|

Vertical

Choker rating of each sling:

6,000 lbs.

Measured Length (L) = 6 ft.

Measured Height (H) = 4 ft.

Reduction Factor (RF) = 4 (H) ÷ 6 (L) = .667 |

|

|

|

|

| Example: |

|

|

|

Load

weight = 1,000 lbs.

Rigging - 2 slings in vertical hitch

Lifting Weight (LW) per sling = 500 lbs.

Measured Length (L) = 10 ft.

Measured Height (H) = 5 ft.

Tension Factor (TF) = 10 (L) ÷ 5 (H) = 2.0

Minimum Vertical Rated Capacity required

for this lift = 500 (LW) x 2.0 (TF) = 1000 lbs.

per sling |

|

Sling

capacity decreases as the angle

from horizontal decreases. Sling angles

of less than 30° are not recommended. |

|

|

Reduced

sling rating in this configuration

= .667 |

|

(RF)

x 6,000 lbs. = 4,000 lbs. of lifting

capacity per sling |

|

|

|

|

|

|

|

Tuflex Polyester

Roundslings with Hardware/Bridle Slings, Lifting Slings, Lift-All,

Bridles, Master-Link, Oblong,

Sling Hook, and Double Leg Bridle from your source for material

handling equipment.

|

Back to Product Page

|

| HOME /

ORDER / SEARCH

/

QUOTE /

CONTACT US / ABOUT

US /

MY ACCOUNT/

SHOPPING CART |

|