Back to Product Page

|

|

|

Drum Handling Slings provide an easy, inexpensive way to handle

steel drums. Available in two styles to

suit your needs for handling drums in the vertical or horizontal

position. |

|

|

|

Vertical

Drum Handling Slings

|

|

|

|

|

Easily

lift standing drums for transport. Tilt suspended

drums to pour from open top or spigot. For use with

ribbed steel drums, the ratcheting belly band tightens

securely below the first rib. |

|

|

|

Heavyweight

sling (DSV602D) uses 2" polyester sling

webbing and is rated at 850 lbs. |

|

|

|

| Promotes

Safety |

|

|

|

•

A wear pad, sewn on one side of the lifting strap, helps to

avoid cutting of the sling.

• Ratchet tightens securely. |

|

|

|

| Saves

Time |

|

|

|

•

Free end of ratchet strap sewn to stay properly threaded.

•Vertical

legs sewn to belly band to maintain proper position. |

|

|

|

To

Order, specify Part No. and drum diameter in inches. i.e.:

DSV602Dx24

(The standard 55 gal. drum has a 24" diameter.) |

|

|

|

|

|

|

|

Horizontal

Drum Handling Slings

|

|

|

|

|

|

Ideal

for the quick and easy moving of steel drums

in the horizontal position. |

|

|

|

|

|

Part

No. DSH601D uses 1" polyester sling webbing

and is rated at 1,500 lbs. |

|

|

|

|

|

Promotes

Safety |

|

|

|

|

|

|

|

•

Strong 1" polyester webbing pulls drum hooks securely into

rims at both ends of the drum during lift. |

|

|

|

|

|

Saves

Time |

|

|

|

|

|

|

|

•

One sling fits multiple size drums.

• Easy to disconnect.

• Uses 1/2" oblong

link at top for easy connection to hoist hook. |

|

|

|

|

|

To

Order, specify Part No. DSH601D. |

|

|

|

|

|

Note:

If using in a chemical environment,

contact us for sling material advice. |

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Price of the item you

wish to purchase.

|

|

|

|

|

PRICING

|

|

Drum Handling Slings Vertical - Standard Heavy Duty |

|

Model No. |

Web

Width (in.)

|

Drum

Dia. (in.)

|

Sling

Cap. (lbs.)

|

Price |

|

DSV602Dx24IN |

2

|

24

|

850

|

|

|

DSV602Dx30IN |

2

|

30

|

850

|

|

|

DSV602Dx36IN |

2

|

36

|

850

|

|

|

Drum Handling Sling Horizontal - Light Duty |

|

DSH601D |

1

|

24

|

300

|

$195.40 |

|

|

|

|

|

|

|

|

|

|

|

| EFFECT

OF SLING ANGLE |

|

|

|

|

|

|

|

|

|

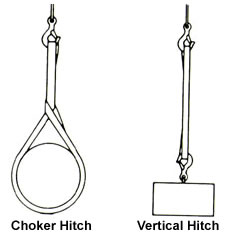

Using

slings at an angle can become deadly if that angle is

not taken into consideration when selecting the sling to

be used. The tension on each leg of the sling is increased as

the angle of lift, from horizontal, decreases. It is most

desirable for a sling to have a larger angle of lift, approaching

90°. Lifts with angles of less than 30° from horizontal

are not recommended. If you can measure the angle of lift or

the length and height of the sling as rigged, you can

determine the properly rated sling for your lift. The Increased

Tension method provides the increased tension as a

function of the sling angle. Alternatively, the sling Reduced

Capacity method may be used to determine reduced lift

capacity for any angle. |

|

|

|

|

|

|

|

|

|

|

INCREASED

TENSION

Determine capacity

of sling needed

|

|

REDUCED

CAPACITY

Calculate rating of each

sling

rigged at this angle

|

|

|

|

|

|

| 1.

Determine the load weight (LW). |

1.

Calculate the reduction factor (RF). |

|

|

|

|

a.

Using the angle from horizontal,

read across the Angle Chart to

the corresponding number of the

Reduction Factor column. |

| 2.

Calculate the Tension Factor [TF]. |

|

|

a.

Determine the sling angle as mea-

sured from the horizontal, and the

corresponding tension factor (TF)

from the effect of angle chart. |

|

|

|

-OR-

|

|

|

b.

Divide sling height* (H) by sling

length* (L). |

|

-OR-

|

|

|

|

b.

Length* (L) divided by height*

(H) |

|

|

|

|

|

2.

Reduction factor (RF) x the sling’s

rated capacity for the type hitch that

will be used = sling’s reduced rating. |

|

|

|

|

|

|

|

|

|

|

|

|

3.

Determine the share of the load

applied to each sling leg (LW). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.

Multiply (LW) by (TF) to determine

the sling leg tension. The capacity of

the selected sling or sling leg must

meet the calculated tension value. |

|

|

*Measured

from a common horizontal

plane to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

*Measured

from a common horizontal plane

to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Effect

of Angle Chart

|

|

|

|

|

Tension

Factor (TF) |

Angle From

Horizontal |

Reduction

Factor (RF) |

|

1.000 |

90º |

1.000 |

|

1.004 |

85º |

0.996 |

|

1.015 |

80º |

0.985 |

|

1.035 |

75º |

0.966 |

|

1.064 |

70º |

0.940 |

|

1.104 |

65º |

0.906 |

|

1.155 |

60º |

0.866 |

|

1.221 |

55º |

0.819 |

|

1.305 |

50º |

0.766 |

|

1.414 |

45º |

0.707 |

|

1.555 |

40º |

0.643 |

|

1.742 |

35º |

0.574 |

|

2.000 |

30º |

0.500 |

|

|

|

|

|

|

|

|

|

Example: |

|

|

|

Vertical

Choker rating of each sling:

6,000 lbs.

Measured Length (L) = 6 ft.

Measured Height (H) = 4 ft.

Reduction Factor (RF) = 4 (H) ÷ 6 (L) = .667 |

|

|

|

|

| Example: |

|

|

|

Load

weight = 1,000 lbs.

Rigging - 2 slings in vertical hitch

Lifting Weight (LW) per sling = 500 lbs.

Measured Length (L) = 10 ft.

Measured Height (H) = 5 ft.

Tension Factor (TF) = 10 (L) ÷ 5 (H) = 2.0

Minimum Vertical Rated Capacity required

for this lift = 500 (LW) x 2.0 (TF) = 1000 lbs.

per sling |

|

Sling

capacity decreases as the angle

from horizontal decreases. Sling angles

of less than 30° are not recommended. |

|

|

Reduced

sling rating in this configuration

= .667 |

|

(RF)

x 6,000 lbs. = 4,000 lbs. of lifting

capacity per sling |

|

|

|

|

|

|

|

Drum Handling

Sling, Webmaster 1600 Slings, Lifting Slings, Sling, Nylon

Slings, Lift-All, Nylon and Polyester Slings, Industrial Standard,

Drum Sling, Heavy Duty Sling, Synthetic Web Slings, Serial

Numbered Identification, Triangles and Chokers, Eye and

Eye Slings, Flat Eye, Twisted Eye, and Endless Slings from

your source for material handling equipment.

|

Back to Product Page

|